Benefit from over 25 years of industry expertise with Atomic System & Design, a leading provider of IC programming services in Singapore. Our value-added services ensure enhanced production efficiency, cost savings, and high reliability while maintaining superior quality standards.

Our principal service covers the provision of programming services and various types of hardware for our customers, with pre-written programmes provided by customers to be coded into the integrated circuits.

We support a wide range of customers, both local and overseas.

- IC Programming

- Package Conversions – Tape and Reel, Tray, Tube

- Component Baking for exposed moisture-sensitive components

- Laser Marking

- Lead Scanning

- ESD Dry Packing with desiccant and humidity indicators

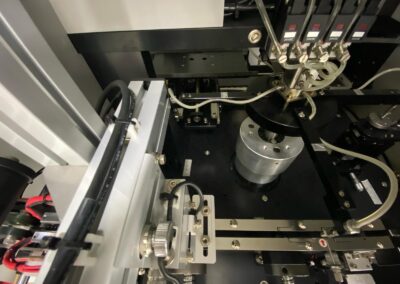

Integrated Circuit (IC) Programming

Our Integrated Circuit (IC) Programming services contribute to increased production line efficiency, saving time and costs during in-circuit testing. We support a wide range of technologies and packages, offering commercially available standard sockets or customized options. With strong vendor relationships, we provide prompt first article turnarounds and can accommodate flexible runs from small prototypes to high-volume production. Supported devices include Memory, MCUs, CPLD, UFS & eMMC in various packages like BGA, QFP, SOIC, SOC, TSOP, and more. Additional services encompass serialization, controlling firmware changes, custom algorithms for encrypted key loading, and embedded trusted certificates, all backed by our commitment to quality and secure programming adhering to ISO 9001 and ISO/IEC 27001 standards.

Tape and Reel

Complementing our IC programming services, our Tape and Reel offerings provide quick, high-quality services to ensure production-ready components. We support Package Conversions – Tray, Tape & Reel, Tube, and handle various components, including Surface Mount Devices, Transistors MOSFETS, Electromechanical, and more.

Baking and Dry Packing

For moisture control, our Baking and Dry Packing services eliminate moisture ingress, especially for older components or those sourced from alternative suppliers. Our temperature and time-controlled ovens cater to delicate and hard-to-handle components, and processed products can be returned in customers’ preferred packaging.

Laser Marking

Facilitate traceability and identification throughout a component’s lifecycle with our Laser Marking services. This non-contact method uses laser thermal effects for pollution-free, fast marking of clear text, model, manufacturer, and other information without damaging the component’s surface.

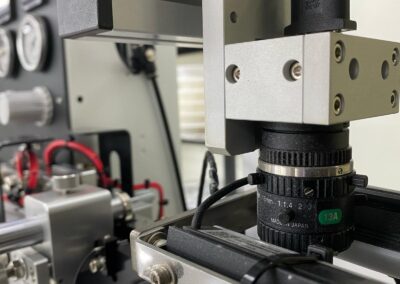

Lead Inspection

Our Lead Inspection services enhance yield and reduce component defects with machine learning, vision-enabled auto-handlers, and standalone inspection machines. Our rigorous quality monitoring detects defects such as scratched, twisted, bent, or missing pins, and includes 3D and 2D inspection capabilities for lead integrity, part orientation, and mark verification.

FIELDS OF APPLICATION

Multiple devices:

Microcontroller, Flash, EPROM and EEPROM, FPGA & PLD, DSP, Microcontroller with Flash base and more

Multiple packages:

BGA, CSP, DIP, LCC, MLF, PGA, PLCC, QFP, SCSP, SO, SOP, SOJ, SOIC, SSOIC, TSOP, TSSOP, and many more

WHY OUTSOURCE PROGRAMMING TO ATOMIC SYSTEM & DESIGN

Achieve better yield

No capital investment

Quick turnaround time

Strict process control for programming

Wide range of support for solid state memory storage devices and packages

Higher cost-effectiveness per-device programming

Reliable and high end programmers for all programming processes

Wide range of socket modules available to support different packages